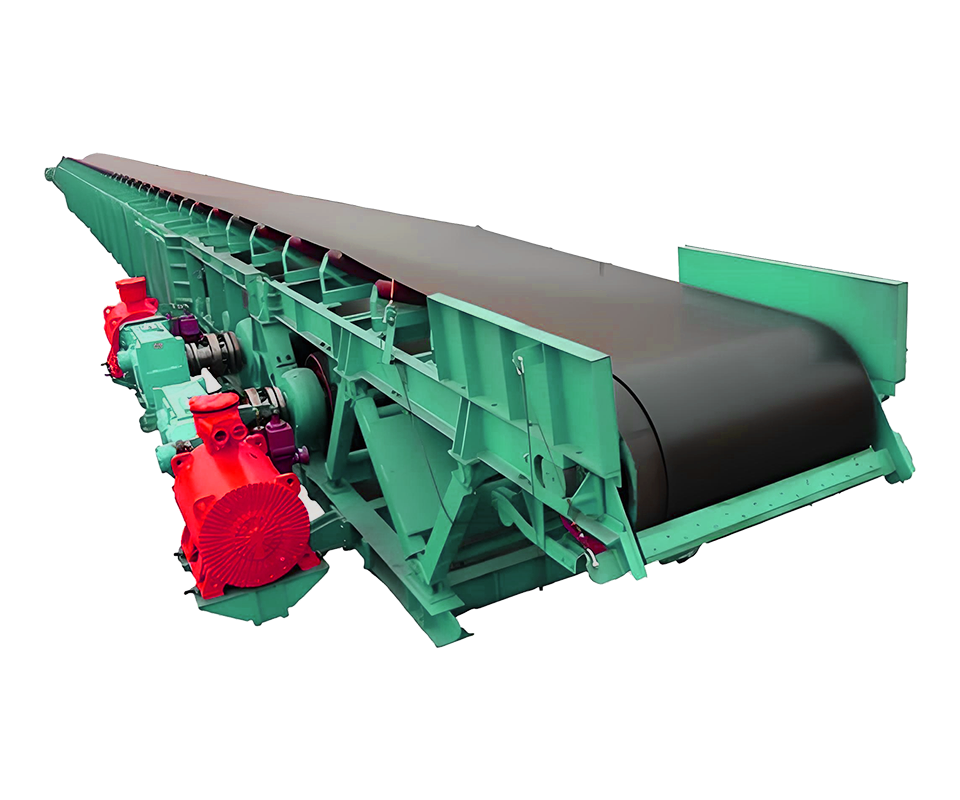

Motor-Driven Vibrating Feeder

Basic vibration feeder for general material dosing applications.

Product Overview

The Motor-Driven Vibrating Feeder is a robust and versatile material handling solution designed for continuous and controlled feeding of bulk materials in industrial applications. Engineered to meet stringent national and international standards (GB/T 13306-1991, GB755-2008, GB4208-2008), this equipment excels in delivering high efficiency, reliability, and adaptability across industries such as mining, metallurgy, chemicals, and construction. Ideal for granular, powdered, or fragmented materials with moderate flow characteristics, it ensures seamless integration into production lines while minimizing operational downtime.

Key Technical Parameters

Design Features

Optional Accessories

Key Technical Parameters

- General Specifications

- Application: Suitable for feeding non-abrasive to semi-abrasive materials, including ores, aggregates, grains, and industrial raw materials.

- Feeding Capacity: ≥60 T/h (adjustable via frequency modulation or manual gate control).

- Material Flow Characteristics: Compatible with materials ≤3 mm in size, including those with poor flowability or mild adhesion properties.

- Operating Temperature: -20°C to +80°C (standard); customized designs available for extreme conditions.

- Drive System

- Motor Specifications:

- Power: Custom-configured based on load requirements (typical range: 0.5–30 kW).

- Efficiency Class: Compliant with GB18613-2020 Grade 2 energy efficiency standards.

- Duty Cycle: S3 (intermittent periodic duty, 40% ED).

- Insulation Class: F (suitable for high-temperature environments).

- Explosion Protection: Ex DIICT5 certification for hazardous environments.

- Starting Method: Direct-on-line (DOL) or variable frequency drive (VFD) options.

- Vibration Parameters:

- Amplitude: Adjustable 2–8 mm (linear or elliptical motion).

- Frequency: 700–3,000 vibrations per minute (VPM).

- Motor Specifications:

- Structural Design

- Trough Construction:

- Material: Carbon steel (standard) or SS304/316 for corrosive/abrasive applications.

- Thickness: ≥6 mm for enhanced durability.

- Lining Options: Replaceable wear-resistant liners (ceramic, polyurethane).

- Support System:

- Springs: High-carbon steel helical springs or rubber isolators for vibration damping.

- Frame: Heavy-duty welded steel with anti-corrosion coating.

- Sealing & Safety:

- Dust Protection: IP65-rated enclosure for motor and drive components.

- Guarding: Compliant with GB4208-2008 for mechanical safety.

- Trough Construction:

- Performance Metrics

- Noise Level: ≤70 dB(A) at 1 m distance (unloaded operation).

- Maintenance Interval: ≥10,000 hours (lubrication-free bearings standard).

- Service Life: ≥10 years under normal operating conditions.

- Electrical & Control

- Voltage: 380 V, 50 Hz, 3-phase.

- Control Interface: Local control panel with overload protection; optional PLC integration.

- Sensors: Built-in vibration monitoring and thermal protection.

- Compliance & Certifications

- Standards: GB/T 13306-1991 (product labeling), GB755-2008 (motor design), GB50254-2014 (electrical installation).

- Testing: Factory acceptance tests (FAT) for vibration stability, load capacity, and safety interlocks.

Design Features

- Modular Construction: Facilitates easy assembly, disassembly, and component replacement.

- Anti-Blocking Design: Optimized trough geometry and vibration profile to prevent material buildup.

- Energy Efficiency: Low-power motors and precision-engineered dynamics reduce energy consumption by up to 30% compared to conventional feeders.

- Adaptability: Configurable for inclined, horizontal, or declined material flow; compatible with hoppers, crushers, or screening systems.

- Primary feeding for crushers, screens, or conveyors in aggregate processing.

- Batch dosing in mixing or batching plants.

- Raw material handling in cement, fertilizer, or food processing industries.

Optional Accessories

- Variable frequency drives (VFD) for precise flow control.

- Wear monitoring systems for predictive maintenance.

- Customized trough sizes (300–2,000 mm width).

- Explosion-proof upgrades for ATEX/IECEx compliance.