Vibratory Screening Feeders

Feeders Compact combo unit integrating feeding and primary screening functions.

Product Overview

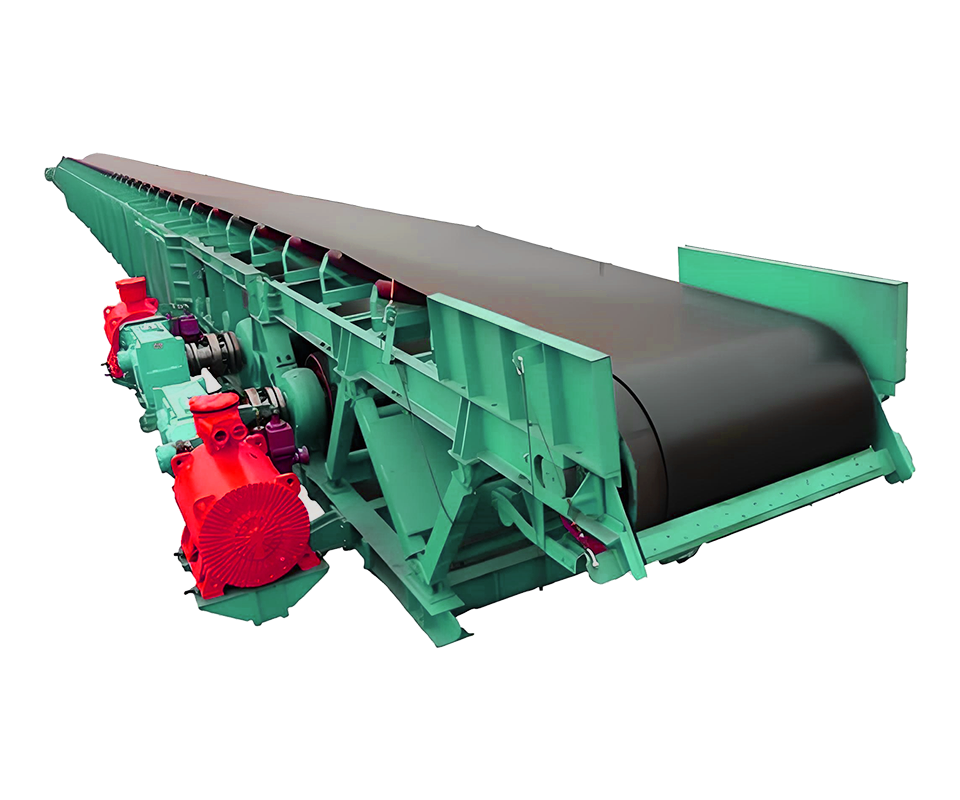

The Vibratory Screening Feeder is an innovative dual-function unit combining precision feeding and primary screening in a single compact footprint. Designed to meet GB/T 13306-1991 and GB/T 755-2008 standards, this equipment streamlines material processing by eliminating the need for separate feeding and screening systems. Ideal for aggregates, recycled materials, and industrial raw materials, it delivers cost savings through reduced floor space requirements and energy-efficient operation.

Key Technical Parameters

Design Innovations

Compliance & Certifications

Operational Advantages

Key Technical Parameters

- General Specifications

- Application: Primary processing of bulk solids (≤150 mm particle size) in mining, recycling, and construction industries.

- Throughput Capacity: 20–500 T/h (material-dependent).

- Screening Efficiency: ≥85% for dry materials; ≥75% for moist/wet applications.

- Operating Temperature: -30°C to +80°C (standard).

- Dual-Function Design

- Feeding System:

- Trough Width: 600–2,400 mm (modular construction).

- Adjustable Feed Rate: 0–100% via variable frequency drive (VFD).

- Screening System:

- Deck Configuration: Single- or double-layer options.

- Mesh Size: 5–150 mm (woven wire or polyurethane panels).

- Deck Angle: 15°–25° adjustable inclination.

- Feeding System:

- Drive & Power

- Vibration Motors:

- Power Range: 2×0.75 kW to 2×22 kW (synchronized counter-rotating).

- Frequency: 700–1,200 RPM (tunable for material characteristics).

- Efficiency: IE3 class (GB 18613-2020 compliant).

- Vibration Amplitude: 3–8 mm (mechanical adjustment).

- Vibration Motors:

- Structural Components

- Frame: Hot-dip galvanized steel (GB/T 13912-2020) or SS304 for corrosive environments.

- Deck Support: Rubber isolators (GB/T 5574-2008) with 90% vibration absorption.

- Wear Protection: Replaceable AR400 steel liners at impact zones.

- Performance Metrics

- Dynamic Load Capacity: ≤20 kN/m².

- Noise Emission: ≤78 dB(A) at 1 m distance (unloaded).

- Maintenance Interval: 8,000–10,000 hours (grease-lubricated bearings).

- Control & Safety

- Operation Modes: Manual, semi-automatic, or PLC-integrated.

- Protections: Motor overload, emergency stop (GB/T 5226.1-2019).

- Enclosure Rating: IP66 for electrical components (GB/T 4208-2017).

Design Innovations

- Space-Saving Layout: 40% smaller footprint vs. traditional feeder-screen setups.

- Twin-Frequency Technology: Independent control of feeding and screening vibrations.

- Quick-Change Screen System: Tool-free mesh replacement within 15 minutes.

- Material Flow Optimization: Cascading baffles prevent blinding and improve stratification.

- Pre-screening crusher feed in quarry operations.

- Contaminant removal in C&D waste recycling.

- Grading limestone/coal in cement plants.

Compliance & Certifications

- Structural Integrity: GB/T 3811-2008 (Design Rules for Cranes, adapted for dynamic loads).

- Vibration Safety: GB/T 25615-2010 (Mechanical vibration requirements).

- Electrical Safety: GB 28526-2012 (Adjustable speed drives).

- Water-spray system for dust suppression.

- IoT-ready vibration sensors for predictive maintenance.

- Explosion-proof motors (Ex IIB T4 per GB 3836).

- Customized deck layouts (wedge wire, punch plate).

Operational Advantages

- 30% Energy Savings: Achieved through optimized mass-spring resonance system.

- Zero Cross-Contamination: Full-depth screening decks with sealed edges.

- Climate Resilience: Winterization kits available for -40°C operations.