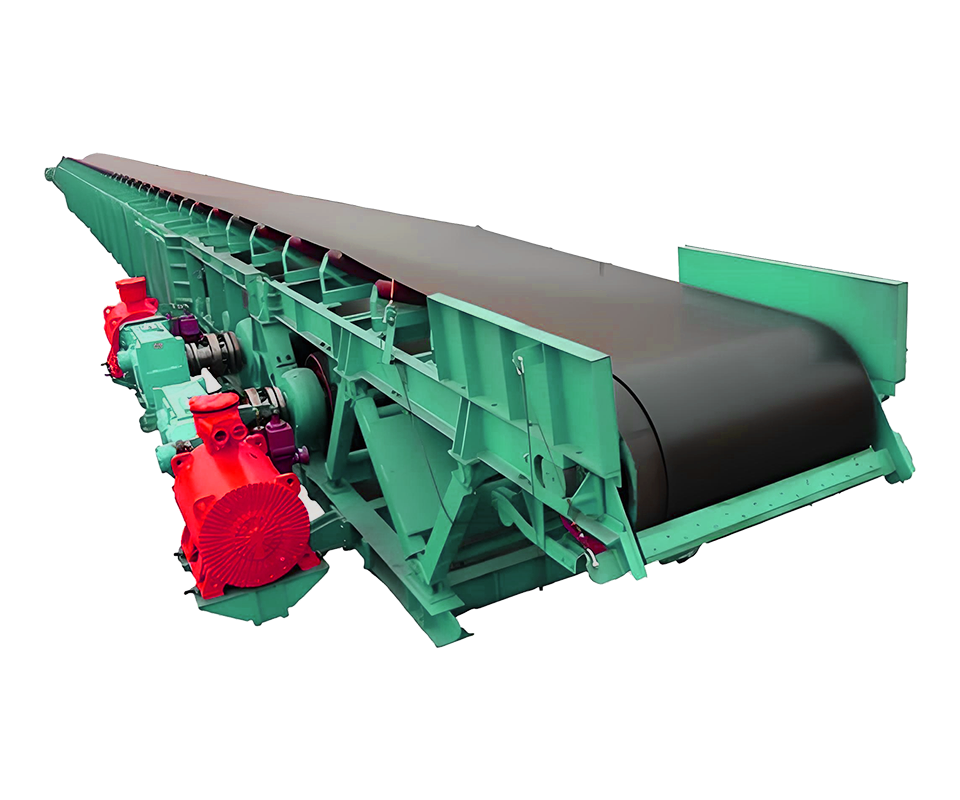

Screw-Trommel Feeders

Combined screw feeder and rotating screen for high-dust/sticky material processing.

Product Overview

The Screw-Trommel Feeder is an integrated processing unit combining precision screw feeding with rotary screening for challenging high-dust and adhesive materials. Compliant with GB/T 36865-2018 (Spiral Conveyor Standards) and GB/T 14521.5-1993 (Terminology for Screening Equipment), this dual-function system eliminates material buildup while ensuring continuous operation in mining, waste recycling, and mineral processing applications.

Key Technical Parameters

Design Innovations

Compliance & Standards

Operational Advantages

Key Technical Parameters

- General Specifications

- Application: Handling sticky/cohesive materials (moisture ≤25%) such as clay-rich ores, municipal sludge, and wet biomass.

- Throughput Capacity: 10–800 T/h (material-dependent).

- Processing Stages: Simultaneous feeding, screening (1–150 mm), and dewatering.

- Positioning: Heavy-duty solution for raw material preprocessing in extreme conditions.

- Screw Feeder Module

- Screw Configuration:

- Diameter: 400–1,200 mm (shaftless design for sticky materials).

- Pitch: 0.8–1.5× diameter (tapered sections available).

- Speed: 5–60 RPM (stepless VFD control).

- Drive System:

- Power: 7.5–160 kW (IE4 efficiency per GB 18613-2020).

- Torque: Up to 250 kN·m (planetary gear reducers).

- Screw Configuration:

- Trommel Screen Module

- Drum Geometry:

- Diameter: 1.5–3.5 m (12-sided polygonal design).

- Length: 4–15 m (modular segments).

- Screen Media: Rubber/PU panels (5–30 mm apertures).

- Rotation System:

- Speed: 8–25 RPM (hydraulic or electromechanical drive).

- Inclination: 3°–7° (adjustable via hydraulic legs).

- Drum Geometry:

- Structural Design

- Frame Construction: Q345B steel (GB/T 1591-2018) with abrasion-resistant coating.

- Sealing System:

- Dust Control: Multi-stage labyrinth seals (GB/T 16911-2008).

- Waterproofing: IP68-rated electrical components.

- Wear Protection:

- Screw Liner: Hardox 450/ceramic composite.

- Trommel Lifter Bars: Replaceable tungsten carbide tips.

- Performance Metrics

- Screening Efficiency: ≥92% for non-sticky materials; ≥85% for adhesive substances.

- Dewatering Rate: Up to 30% moisture reduction.

- Noise Level: ≤82 dB(A) at 1 m (loaded operation).

- Maintenance Interval: 5,000 hours (centralized lubrication system).

Design Innovations

- Self-Cleaning Mechanism: High-frequency vibrators (50–100 Hz) prevent screen blinding.

- Material Flow Optimization: Reverse-pitch screw segments break agglomerates.

- Hybrid Drive System: Combines hydraulic rotation (trommel) with electric screw control.

- Quick-Change Screen: Modular panels replaceable in ≤2 hours.

- Pre-screening clay-bound iron ore in beneficiation plants.

- Organics separation in C&D waste recycling.

- Primary processing of oil sands in energy sectors.

Compliance & Standards

- Mechanical Safety: GB/T 15706-2012 (Integrated risk assessment).

- Explosion Protection: GB 3836.1-2010 (Ex tD IIIB T130°C for dust environments).

- Welding Standards: GB/T 12467-2017 (Non-destructive testing Level II).

- Hot-oil heating system for frozen materials.

- AR 400 steel trommel with replaceable bolt-on liners.

- AI-powered blockage prediction system.

- Dual-water spray bars (60 bar pressure).

Operational Advantages

- 25% Energy Savings: Regenerative braking captures trommel rotation energy.

- Zero Downtime Design: Split housing allows in-situ screw maintenance.

- Climate Adaptability: Winterized bearings (-40°C) and tropical cooling fans (+55°C).