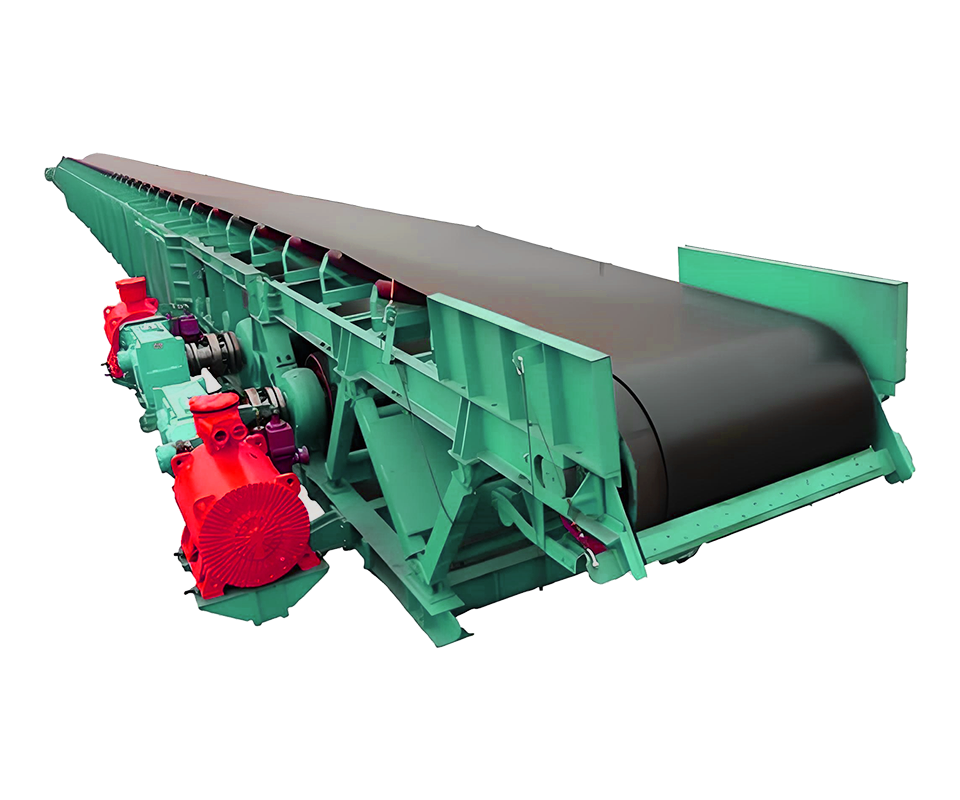

Apron Feeders

Heavy-duty plate feeder with three load classes and dual sealing configurations.

Product Overview

The Heavy-Duty Apron Feeder series is engineered for extreme material handling applications where traditional conveyors fail. Featuring three load classes (LC1-LC3) and dual sealing configurations, this equipment complies with GB/T 3668-2001 (Apron Feeder Technical Specifications) to deliver unmatched reliability in mining, quarrying, and smelting operations. Capable of handling lump sizes up to 2,500 mm and temperatures exceeding 400°C, it serves as the backbone of primary crushing circuits and stockyard reclaim systems.

Key Technical Parameters

Design Innovations

Compliance & Standards

Operational Advantages

Key Technical Parameters

- General Specifications

- Application: Feeding abrasive/hot materials (e.g., iron ore, blast furnace slag, granite) with bulk densities ≤3.2 T/m³.

- Capacity Range:

- LC1: 50–800 T/h (standard duty).

- LC2: 800–2,000 T/h (heavy duty).

- LC3: 2,000–5,000 T/h (extra-heavy duty).

- Material Size: ≤80% of pan width (max. 2.5 m lumps).

- Structural Components

- Pan Assembly:

- Width: 1,000–3,500 mm (GB/T 3668-2001 compliant).

- Material: NM400 steel pans with replaceable Hardox 500 liners.

- Overlap: 50–150 mm (dust-proof design).

- Chain System:

- Type: Forged alloy steel crawler chains (GB/T 36310-2018).

- Tensile Strength: 800–1,500 kN (Class B to D per ISO 4348).

- Pan Assembly:

- Drive & Power

- Motor System:

- Power Range: 15–1,250 kW (IE5 ultra-premium efficiency).

- Speed Control: Hydraulic variable displacement or VFD-driven.

- Speed Range: 0.005–0.5 m/s (stepless adjustment).

- Motor System:

- Sealing Configurations

- Option A: Labyrinth + scraper seals (dust emission ≤10 mg/m³ per GB 16297-1996).

- Option B: Spring-loaded rubber seals + air purge system (IP66 rating).

- Performance Metrics

- Impact Resistance: 50 kJ energy absorption at feed points.

- Slope Capacity: 25° uphill/15° downhill operation.

- Maintenance Interval: 15,000 hours (sealed-for-life bearings).

- Service Life: ≥12 years (LC1/LC2), ≥8 years (LC3).

Design Innovations

- Modular Pan System: Bolt-on liner replacement without disassembling chains.

- Dual-Pivot Design: Articulated frames absorb shock loads up to 500 tonnes.

- Smart Lubrication: Centralized greasing with IoT-enabled pressure monitoring.

- Spillage Control: Curved sideplates + V-shaped trough for 0.1% spillage rate.

- Primary feed systems for gyratory crushers.

- Hot clinker handling in cement plants.

- Overburden removal in open-pit coal mines.

Compliance & Standards

- Structural Integrity: GB/T 3811-2008 (Crane Design Code adapted for dynamic loads).

- Welding Quality: GB/T 12469-2017 (Level I radiographic testing).

- Noise Control: GB 12348-2008 (≤85 dB(A) at 1 m).

- Water-cooled pans for molten slag handling.

- RFID-enabled wear liner tracking system.

- Explosion-proof package (Ex IIB T4 per GB 3836.1-2010).

- Autonomous load-sensing via strain gauge arrays.

Operational Advantages

- 40% Energy Savings: Regenerative drives recover downhill braking energy.

- Zero Downtime: Split sprockets allow onsite shaft repairs.

- Universal Compatibility: Frames adapt to Komatsu/Caterpillar track chains.