Rotary Vane Feeders

Hard-geared reducer with VFD motor for precise material control in pneumatic systems.

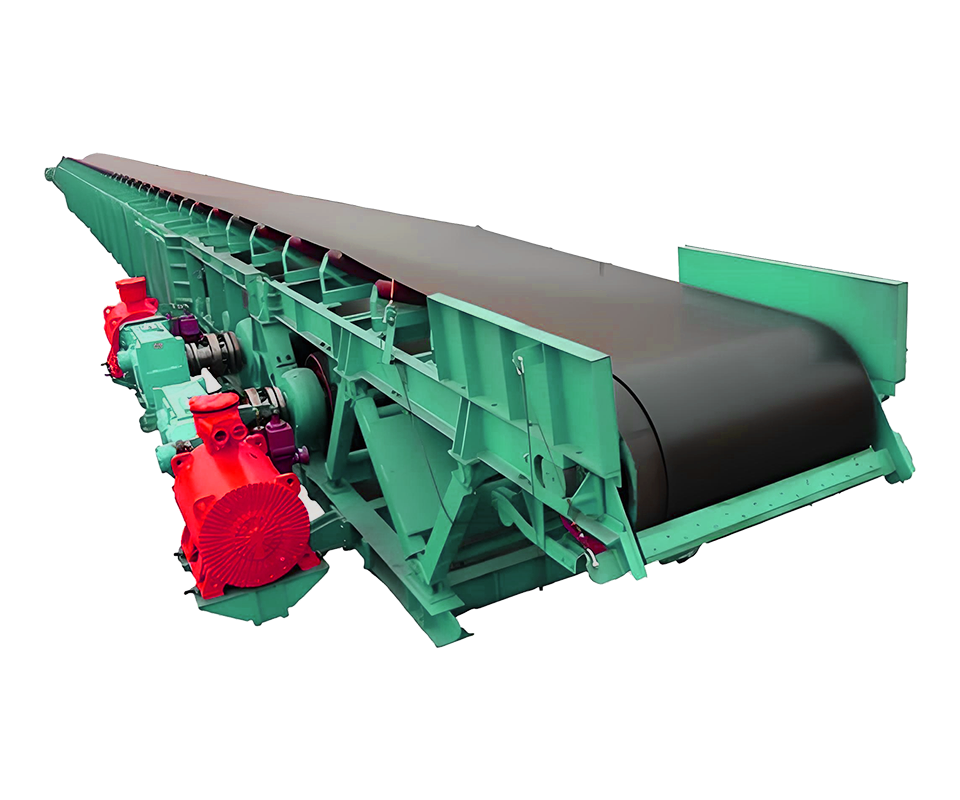

Product Overview

The Rotary Vane Feeder is a precision-engineered volumetric feeding solution designed for pneumatic conveying systems requiring airtight material control. Equipped with a hardened gear reducer and variable frequency drive (VFD) motor, this equipment complies with GB/T 10085-2018 (Gear Reducer Standards) and GB 755-2008 (Rotating Electrical Machinery) to deliver ±0.5% material dosing accuracy in cement, food, and chemical industries. Its robust construction ensures reliable operation under pressures up to 0.35 MPa, making it ideal for both vacuum and positive-pressure systems.

Key Technical Parameters

Design Innovations

Compliance & Standards

Operational Advantages

Key Technical Parameters

- General Specifications

- Application: Handling free-flowing to semi-cohesive powders (≤5 mm) with bulk densities 0.3–1.8 T/m³.

- Capacity Range: 0.1–300 m³/h (adjustable via VFD).

- Material Temperature: -30°C to +280°C (high-temp variants available).

- Positioning: Premium solution for dust-tight batch processes.

- Drive System

- Gear Reducer:

- Type: Helical-hardened gears (AGMA 13 accuracy class).

- Ratio: 7.5–100:1 (GB/T 10085-2018 compliant).

- Efficiency: ≥96% at full load.

- Motor System:

- Power: 0.55–90 kW (IE5 ultra-premium efficiency per GB 18613-2020).

- Frequency Control: Vector-duty VFD with 0.01 Hz resolution.

- Gear Reducer:

- Vane & Housing

- Rotor Assembly:

- Vanes: 8–12 chrome-plated vanes (HRC 58–62 hardness).

- Clearance: 0.05–0.15 mm (adjustable wear compensation).

- Chamber Design:

- Material: Cast iron (GG25) or SS316L (GB/T 2100-2017).

- Sealing: Triple-lip seals + purge air ports (leakage <0.1% vol).

- Rotor Assembly:

- Performance Metrics

- Speed Range: 1–40 RPM (linear torque characteristics).

- Pressure Rating: 0.35 MPa (standard); 1.0 MPa (explosion-proof variants).

- Noise Level: ≤72 dB(A) at 1 m.

- Maintenance Interval: 20,000 hours (grease-packed lifetime bearings).

Design Innovations

- Zero-Pulse Dosing: Anti-cavitation vanes eliminate material pulsation.

- Quick-Release Covers: Tool-free access for vane replacement in ≤15 minutes.

- Thermal Management: Air/water-cooled housing for high-temp applications.

- Smart Calibration: Auto-tuning via integrated load cells (OIML R61 Class 0.2).

- Fly ash injection in coal-fired power plants.

- Seasoning dosing in instant food production.

- Activated carbon transfer in wastewater treatment.

Compliance & Standards

- Mechanical Safety: GB/T 15706-2012 (Risk assessment for dust zones).

- Explosion Protection: GB 3836.1-2010 (Ex tD IIIB T135°C).

- Hygienic Design: GB 4806.1-2016 (Food contact surface Ra ≤0.8 µm).

- CIP/SIP-ready sanitary design (3-A certification).

- Tungsten carbide-coated vanes for abrasive materials.

- IoT-enabled predictive maintenance interface.

- Nitrogen purging system for combustible dusts.

Operational Advantages

- 35% Energy Savings: Regenerative VFDs recover deceleration energy.

- Zero Cross-Contamination: FDA-grade seals for pharma applications.

- Plug-and-Play Integration: MODBUS RTU/PROFINET protocols.