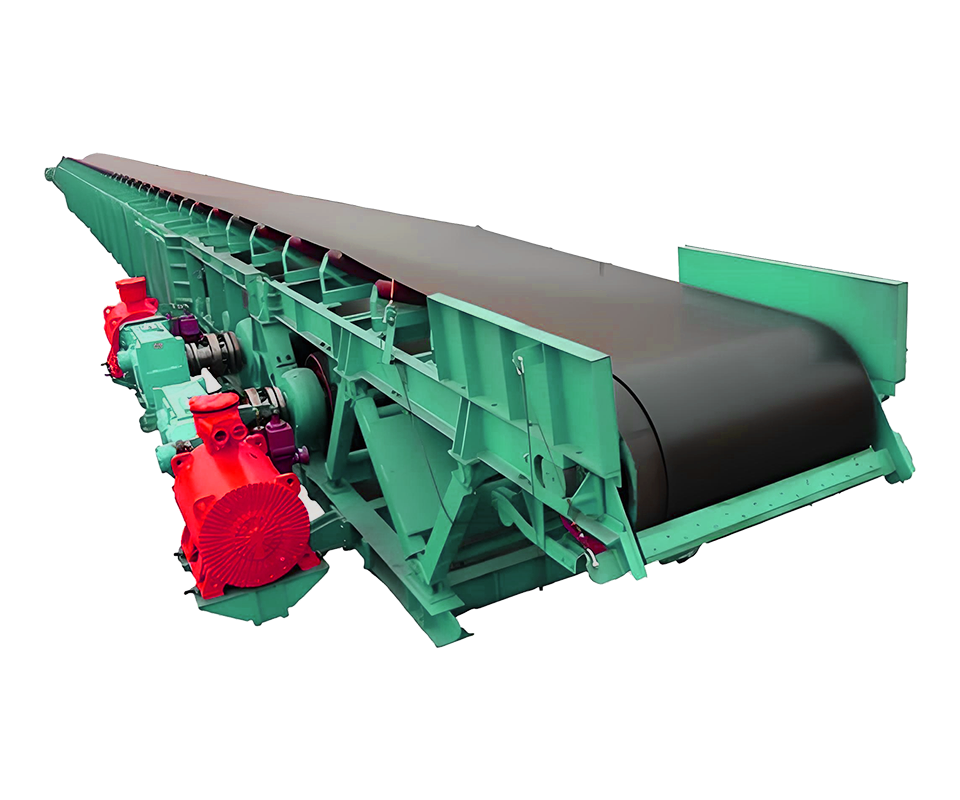

Gravimetric Feeders

Precision weighing feeder with explosion-proof/hermetic options for controlled dosing.

Product Overview

The Gravimetric Feeder series represents the pinnacle of precision dosing technology, integrating real-time weight measurement with closed-loop control for critical material handling applications. Compliant with GB 3836.1-2010 (Explosive Atmospheres) and GB/T 7721-2017 (Automatic Gravimetric Filling Instruments), this equipment delivers ±0.25% dosing accuracy in pharmaceutical, chemical, and food processing industries. Available in explosion-proof and hermetic configurations, it ensures safe operation in ATEX Zone 21/22 environments and GMP-regulated cleanrooms.

Key Technical Parameters

Design Innovations

Compliance & Standards

Operational Advantages

Key Technical Parameters

- General Specifications

- Application: Metering powders, pellets, and flakes (bulk density 0.2–2.5 T/m³) with hygroscopic or electrostatic properties.

- Capacity Range: 0.1 kg/h–50 T/h (multi-range load cells).

- Dosing Accuracy:

- Static: ±0.1% of setpoint.

- Dynamic: ±0.25% under load fluctuations.

- Positioning: Premium solution for FDA/GMP-compliant production lines.

- Weighing System

- Load Cell:

- Type: Monolithic shear beam (OIML R60 Class 0.02).

- Sampling Rate: 1,000 Hz (anti-vibration filtering).

- Control Algorithm: Adaptive PID with neural network tuning.

- Load Cell:

- Drive & Feed Mechanism

- Screw/Belt Options:

- Screw: Twin- or single-screw (1–300 mm diameter).

- Belt: FDA-grade PU belts (200–1,500 mm width).

- Motor System:

- Power: 0.25–30 kW (IE5 SynRM motors, GB 18613-2020).

- Speed Control: 0.01–100% stepless adjustment via VFD.

- Screw/Belt Options:

- Safety & Containment

- Explosion Proof:

- Standard: Ex d IIC T4 Gb (GB 3836.1-2010).

- Options: Ex tD IIIB T130°C for combustible dusts.

- Hermetic Design:

- Sealing: Double mechanical seals + gas purge (leakage <1 ppm).

- Pressure Rating: -0.095 MPa to +0.7 MPa.

- Explosion Proof:

- Structural Components

- Frame: SS316L (GB/T 3280-2015) with electropolished finish (Ra ≤0.4 µm).

- Contact Surfaces:

- Coatings: FDA-compliant PTFE or ceramic (GB 4806.1-2016).

- Enclosure Rating: IP66/IP69K (GB/T 4208-2017).

Design Innovations

- Self-Calibration: Automatic span adjustment via built-in test weights.

- Material Bridge Breaker: Ultrasonic/VFD-controlled agitators.

- Quick-Change System: Tool-free disassembly for <10-minute CIP cycles.

- Smart Diagnostics: AI-powered wear prediction for screws/belts.

- API ingredient dosing in tablet compression.

- Flame retardant addition in polymer extrusion.

- Seasoning application in snack food production.

Compliance & Standards

- Weighing Accuracy: GB/T 7721-2017 Class 0.5.

- Hygienic Design: GB 4806.1-2016 + EHEDG EL Class I.

- Electrical Safety: GB 5226.1-2019 (PLd safety level).

- Nitrogen inertization system (O₂ <1%).

- X-ray detectable belt/screw variants.

- 21 CFR Part 11-compliant software.

- Infrared moisture compensation system.

Operational Advantages

- 40% Energy Savings: Regenerative drives recover braking energy.

- Zero Downtime: Hot-swappable load cells and drives.

- Universal Connectivity: OPC UA, MQTT, and PROFINET protocols.