- Classification

ERTONG Feeders includes motor vibratory, electromagnetic vibratory (for metallurgy), belt (air-tight/pressure-resistant with variable frequency control), screw (multi-configurations for chemicals), screen-integrated, roller-screw, plate (light/heavy-duty), and impeller feeders. Designed for precision, durability, and handling diverse materials like dusty or adhesive loads. Ideal for mining, chemical, and bulk processing industries.

- Line up

Type of Feeders

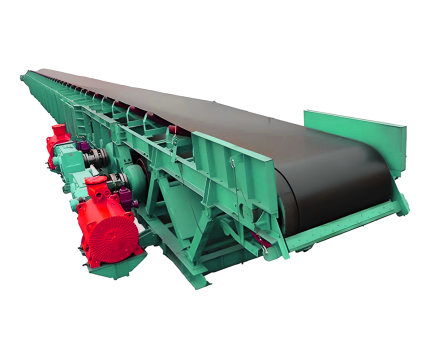

Belt Feeders

Sealed belt feeder with frequency control for precise digital dosing (pressure/hermetic variants).

Electromagnetic Vibrating Feeders

Precision feeder for metallurgical processes, being phased out by belt feeders.

Gravimetric Feeders

Precision weighing feeder with explosion-proof/hermetic options for controlled dosing.

Rotary Vane Feeders

Hard-geared reducer with VFD motor for precise material control in pneumatic systems.

Screw Feeders

Multi-screw configurations (1-5 screws) in horizontal/vertical arrangements for chemical industry.

Screw-Trommel Feeders

Combined screw feeder and rotating screen for high-dust/sticky material processing.

Vibratory Screening Feeders

Feeders Compact combo unit integrating feeding and primary screening functions.