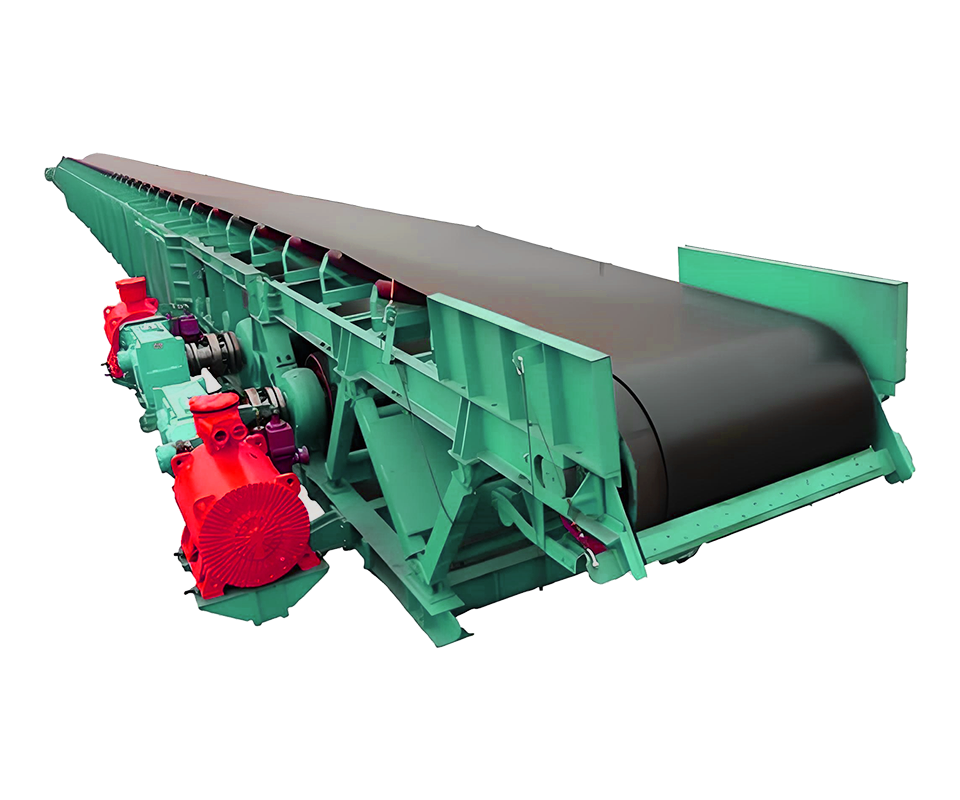

Belt Feeders

Sealed belt feeder with frequency control for precise digital dosing (pressure/hermetic variants).

Product Overview

The Sealed Belt Feeder is an advanced dosing solution engineered for precision material handling in demanding industrial environments. Combining hermetic sealing technology with digital frequency control, this equipment delivers ±0.5% dosing accuracy while preventing material contamination and dust emissions. Compliant with GB/T 10595 (Belt Conveyor Technical Specifications) and GB 50431 (Design Code for Belt Conveyor Engineering), it serves critical applications in chemical processing, food production, and pneumatic conveying systems requiring pressure-rated containment.

Key Technical Parameters

Design Innovations

Compliance & Standards

Operational Advantages

Key Technical Parameters

- General Specifications

- Application: Metered feeding of powders, granules, and fragile materials (≤50 mm) under atmospheric or pressurized conditions (-5 kPa to +50 kPa).

- Capacity Range: 0.1–1,500 T/h (adjustable via frequency modulation).

- Material Temperature: -40°C to +220°C (standard), with high-temperature variants up to 400°C.

- Positioning: Premium-grade solution for hygienic/explosive environments.

- Belt System

- Belt Type:

- Pressure Variant: Steel-reinforced rubber belt (GB/T 4490) with IP69K-rated sealing.

- Hermetic Variant: FDA-compliant PU belt with gas-tight clamps.

- Belt Width: 300–2,000 mm (GB 987 compliance).

- Belt Speed: 0.005–1.5 m/s (digital linear control).

- Belt Type:

- Drive & Control

- Motor System:

- Power: 0.37–55 kW (IE4 efficiency per GB 18613-2020).

- Frequency Converter: Vector-controlled VFD with 0.01 Hz resolution.

- Dosing Accuracy:

- Static: ±0.25% of set value.

- Dynamic: ±0.5% under load fluctuations.

- Motor System:

- Sealing Technology

- Primary Seal: Labyrinth + silicone wiper dual barriers (GB/T 14211-2019 leakage <0.1 mg/m³).

- Secondary Containment: Removable transparent covers (5 mm polycarbonate).

- Purge Ports: NACE-compliant nitrogen/air injection for explosive atmospheres.

- Structural Design

- Frame: SS304/316L (GB/T 3280-2015) or carbon steel with epoxy coating.

- Idlers: Sealed bearings with CIP/SIP compatibility (GB/T 24611-2020).

- Inlet/Outlet: ASME B16.5 flanges or sanitary tri-clamp connections.

- Performance Metrics

- Noise Level: ≤68 dB(A) at 1 m.

- Maintenance Interval: 15,000 hours (grease-free drum bearings).

- Service Life: ≥10 years (belt replacement cycle: 20,000–50,000 h).

Design Innovations

- Smart Dosing Suite: Integrates load cells (OIML R60 Class 0.5) and laser scanners for real-time mass flow correction.

- Quick-Release Seals: Tool-free disassembly for cleaning within 30 minutes.

- Pressure Compensation: Automatic bleed valves maintain seal integrity under vacuum/pressure cycles.

- Modular Construction: Stackable units for multi-stage dosing processes.

- Precision additive feeding in catalyst production.

- Closed-loop material transfer in lithium battery manufacturing.

- Explosion-proof dosing for coal injection systems (ATEX/GB 3836 compliant).

Compliance & Standards

- Mechanical Safety: GB/T 14784-2013 (Belt Conveyor Safety Code).

- Explosion Protection: GB 3836.1-2010 (Ex db IIC T4 Gb).

- Hygienic Design: GB 4806.1-2016 (Food Contact Material Safety).

- AI-powered predictive maintenance interface.

- Liquid-cooled housing for extreme temperatures.

- X-ray detectable belt variants (pharmaceutical GMP).

- Integrated metal detection/rejection system.

Operational Advantages

- 50% Energy Savings: Regenerative drives recover braking energy.

- Zero Cross-Contamination: Meets WHO Annex 1 requirements for sterile processes.

- Plug-and-Play Automation: PROFIBUS/Modbus TCP protocols for Industry 4.0 integration.