Electromagnetic Vibrating Feeders

Precision feeder for metallurgical processes, being phased out by belt feeders.

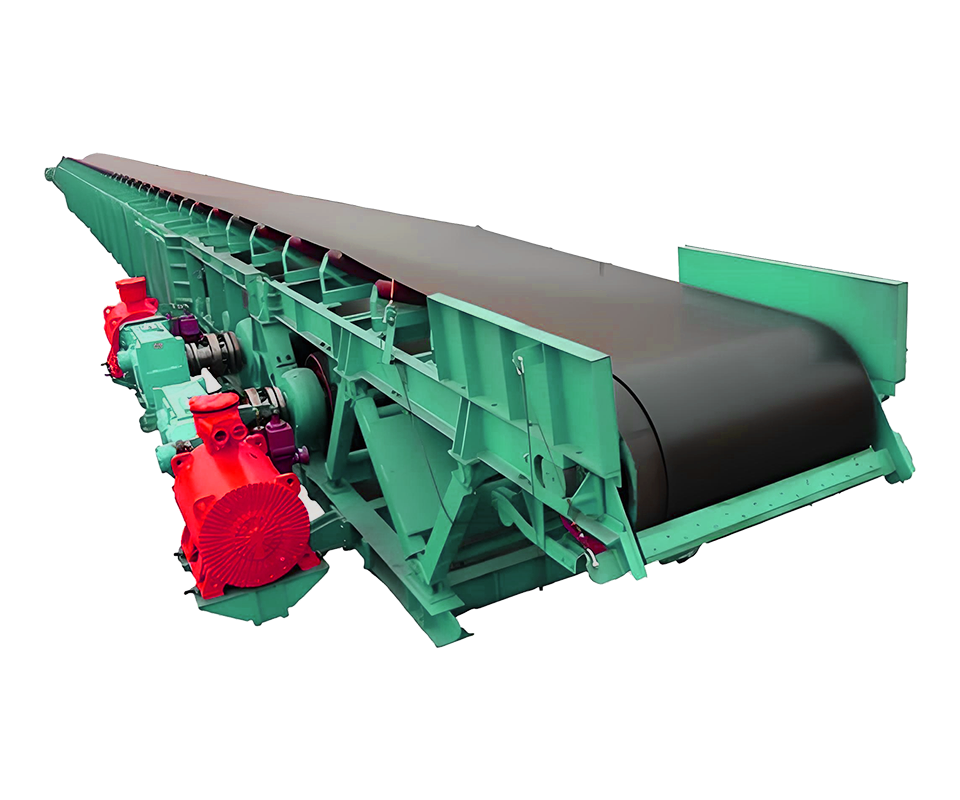

Product Overview

The Electromagnetic Vibrating Feeder is a precision material handling device traditionally employed in metallurgical and industrial processes for controlled feeding of bulk solids. While gradually being superseded by modern belt feeders in some applications, this equipment remains relevant in scenarios requiring ultra-fine material control, high-frequency operation, or compact installations. Compliant with GB/T 13306-1991 and GB/T 755-2008 standards, it serves as a cost-effective solution for low-to-medium capacity systems where material degradation must be minimized.

Key Technical Parameters

Design Features

Compliance & Standards

Product Positioning Positioned as a niche solution for specialized metallurgical processes, this feeder caters to facilities prioritizing precise material control over operational efficiency. It serves as an interim option for plants undergoing phased modernization, with full technical support for legacy system integration. Note: Production of this model may be discontinued after 2025. Contact our team for migration plans to next-gen feeding systems.

Key Technical Parameters

- General Specifications

- Application: Ideal for granular/powdered materials ≤5 mm in size, including metal powders, mineral concentrates, and abrasive additives.

- Feeding Capacity: 0.1–50 T/h (adjustable via voltage regulation or amplitude control).

- Material Temperature: ≤120°C (standard); high-temperature variants available up to 300°C.

- Positioning: Transitional solution for legacy systems; recommended for low-budget, precision-focused operations.

- Drive System

- Electromagnetic Exciter:

- Power Supply: 220/380 V AC, 50 Hz.

- Frequency: 3,000–6,000 vibrations per minute (VPM).

- Adjustability: Continuous amplitude control (0–100% output).

- Duty Cycle: S2 (short-time duty) or S3 (intermittent periodic duty).

- Energy Efficiency: Class IE2 compliance (GB 18613-2020).

- Electromagnetic Exciter:

- Structural Design

- Trough Construction:

- Material: 304 stainless steel (standard) or manganese steel for abrasive materials.

- Thickness: 4–8 mm (corrosion-resistant coating optional).

- Geometry: U-shaped or tubular configurations.

- Suspension System:

- Springs: Leaf springs or helical springs with anti-resonance design.

- Isolation: Rubber buffers for vibration damping (GB/T 5574-2008).

- Trough Construction:

- Performance Metrics

- Feed Accuracy: ±2% under stable material conditions.

- Noise Level: ≤75 dB(A) at 1 m distance.

- Maintenance Cycle: 5,000–8,000 hours (brush replacement in exciters).

- Control & Safety

- Operation Modes: Manual voltage regulation or automated PLC integration.

- Protections: Overload cut-off, thermal sensors (GB/T 14048.1-2012).

- Enclosure Rating: IP54 (standard), upgradable to IP65 for dusty environments.

Design Features

- Precision Control: Micro-adjustable vibration intensity for delicate material handling.

- Zero Material Contamination: Non-contact drive mechanism eliminates lubricant risks.

- Compact Footprint: 30–50% smaller than equivalent belt feeders.

- Low Maintenance: No rotating parts except exciters; simplified lubrication points.

- Batch dosing in induction furnaces (metallurgical plants).

- Powder injection systems for alloy production.

- Legacy cement kiln feed systems.

Compliance & Standards

- Mechanical Safety: GB/T 15706-2012

- Vibration Testing: GB/T 10068-2020

- Electromagnetic Compatibility: GB 4824-2019

- Explosion-proof design (Ex tD IIIC T80°C) for combustible dust environments.

- Wear-resistant ceramic liners (3–6 mm thickness).

- IoT-enabled condition monitoring sensors.

Product Positioning Positioned as a niche solution for specialized metallurgical processes, this feeder caters to facilities prioritizing precise material control over operational efficiency. It serves as an interim option for plants undergoing phased modernization, with full technical support for legacy system integration. Note: Production of this model may be discontinued after 2025. Contact our team for migration plans to next-gen feeding systems.