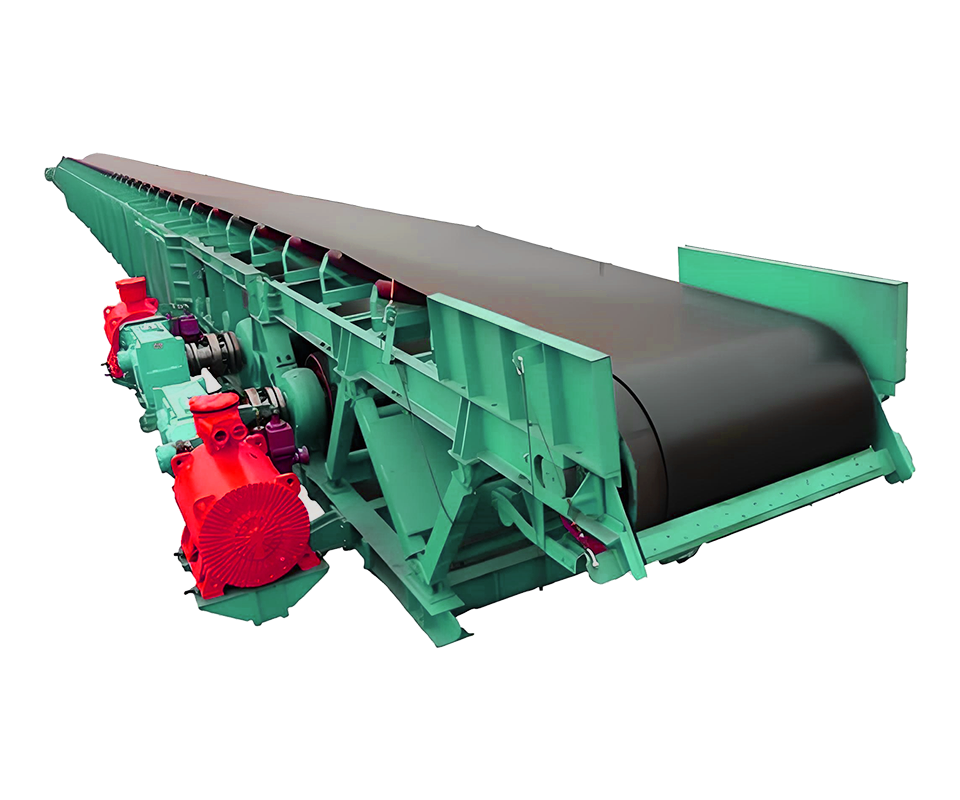

High-Temperature Conveyors

Heat-resistant conveyor for hot materials (up to 400°C) with optional

Overview

The High-Temperature Conveyor System is engineered to transport materials at extreme temperatures, from molten metals to sintered ores, while maintaining operational integrity and safety. With an optional thermal insulation package, this system minimizes heat loss for processes requiring consistent material temperatures. Compliant with GB/T standards, it serves foundries, cement plants, glass manufacturing, and other industries demanding reliable high-heat material handling.

Key Features

Design & Compliance

- Extreme Heat Resistance

- Standard operation: 200°C to 400°C; insulated models extend to 1,200°C with ceramic fiber blankets.

- Heat-resistant chains/belts (Ni-Cr alloy or silicon carbide-coated) withstand thermal cycling ≥10,000 times.

- Thermal Management

- Active cooling system (optional): Water-cooled rollers or air jets reduce belt temperature to <100°C at drive units.

- Insulation efficiency: ≤5% heat loss per meter (insulated models) at 400°C ambient.

- Expansion Compensation

- Self-aligning rollers accommodate thermal expansion (±15 mm/m).

- Laser-guided tracking maintains ±3 mm belt alignment at full load.

| Parameter | Standard Model | Insulated Model |

| Max Material Temperature | 400°C | 1,200°C |

| Belt/Chain Material | 310S Stainless Steel | Ceramic Fiber Composite |

| Belt Width | 500–2,500 mm | 600–3,000 mm |

| Speed Range | 0.1–10 m/min | 0.05–5 m/min |

| Power Requirements | 7.5–250 kW | 15–400 kW |

| Heat Loss Rate | N/A | ≤5% per meter (at 800°C) |

| Cooling System | Air-cooled bearings (standard) | Water-cooled rollers (optional) |

- Fire Safety: Spark-resistant construction meets GB/T 1771 flame spread requirements.

- Structural Integrity: 1.5× safety factor for load capacity (GB/T 10595 compliance).

- Insulation Package: Multi-layer ceramic fiber (1,260°C rating) + aluminum foil reflectors.

- Metallurgy: Hot ingots, slag, and calcined alumina transport.

- Glass Industry: Molten glass cullet and formed bottle handling.

- Cement Production: Clinker cooling and kiln feed systems.

- Energy Sector: Biomass ash and incinerator residue conveyance.

- Heat Recovery: Integrate waste heat boilers for steam generation.

- Smart Monitoring: Infrared thermal cameras + AI-based anomaly detection.

- Specialized Belts: Magnetic plates for steel scraps, corrugated edges for powders.

- Explosion Proof: ATEX-certified models for combustible dust environments.

- Unmatched Durability: 10-year lifespan in 400°C continuous operation (documented cases).

- Energy Efficiency: Insulated models reduce energy consumption by 35% vs. uninsulated rivals.

- Safety Assurance: Automatic emergency shutdown if belt temperature exceeds 1,300°C.

- Quick ROI: 12–18 month payback through reduced downtime and energy savings.

- Thermal Testing: Prototype validation at 1.2× rated temperature for 500 hours.

- Warranty: 3-year structural warranty, 1-year insulation integrity.

- Delivery: 16–24 weeks (standard); expedited insulated units in 20 weeks.