Screw Feeders

Multi-screw configurations (1-5 screws) in horizontal/vertical arrangements for chemical industry.

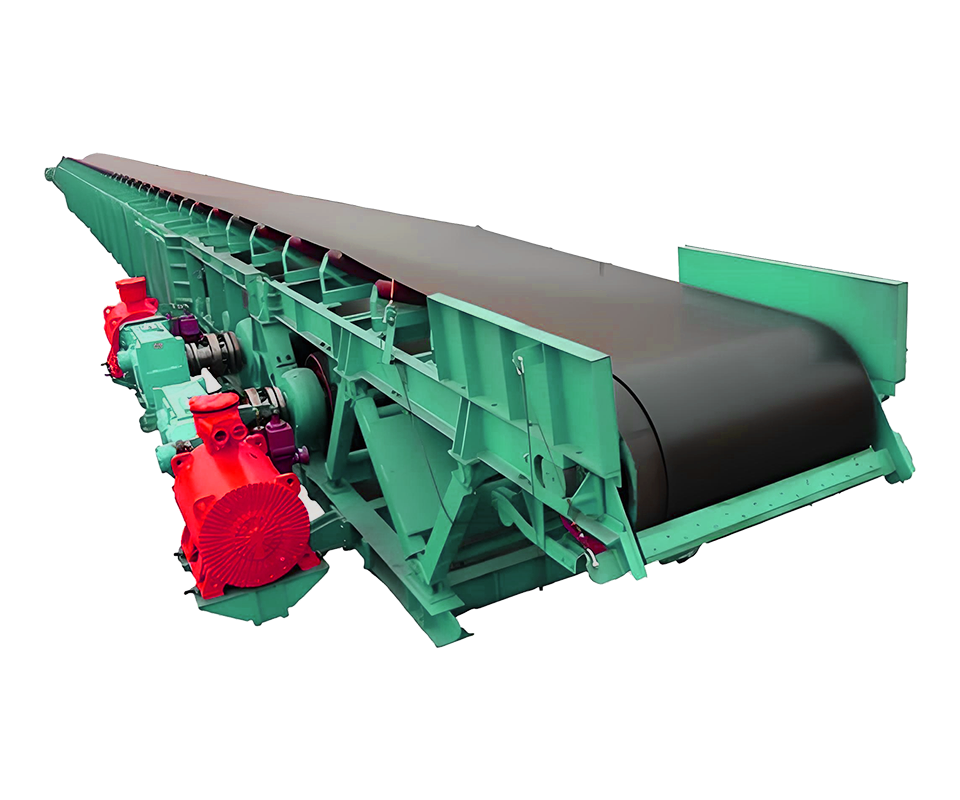

Product Overview

The Multi-Screw Feeder series is a highly customizable material handling solution engineered for precision dosing and bulk solid transfer in chemical manufacturing processes. Featuring modular 1-5 screw configurations with horizontal or vertical orientations, this equipment complies with GB/T 36865-2018 (Spiral Conveyor Standards) to ensure reliable operation in corrosive, abrasive, or explosive environments. Ideal for polymers, catalysts, and hygroscopic powders, it bridges the gap between batch processing and continuous production lines.

Key Technical Parameters

Design Innovations

Compliance & Standards

Operational Advantages

Key Technical Parameters

- General Specifications

- Application: Handling materials with bulk densities 0.2–2.5 T/m³, including sticky, heat-sensitive, or explosive substances (ST1/ST2 dusts).

- Capacity Range: 0.05–300 m³/h (variable via screw speed/pitch adjustment).

- Material Temperature: -50°C to +450°C (jacketed variants available).

- Positioning: Premium solution for high-mix, low-volume chemical production.

- Screw System

- Configuration Options:

- Single Screw: Standard U-trough design (GB/T 36865-2018 compliant).

- Multi-Screw: 2–5 parallel screws with synchronized drives (center distances 150–600 mm).

- Screw Geometry:

- Diameter: 100–600 mm (ISO 2140 tolerance class).

- Pitch: 0.8–1.2× screw diameter (variable pitch sections optional).

- Rotation Speed: 5–150 RPM (stepless control).

- Configuration Options:

- Drive & Power

- Motor System:

- Power Range: 0.55–90 kW (Ex d IIC T4 motors per GB 3836.1-2010).

- Gearbox: Helical or planetary reducers (GB/T 19073-2018).

- Control Precision:

- Speed Stability: ±0.1% under load (encoder feedback).

- Dosing Accuracy: ±0.3% of set value.

- Motor System:

- Structural Design

- Trough/Barrel:

- Material: SS304/316L (GB/T 3280-2015), Hastelloy®, or ceramic-lined.

- Sealing: Gas-tight PTFE lip seals + purge ports (leakage <10 ppm).

- Shaft Assembly:

- Type: Solid shaft (standard) or shaftless (for sticky materials).

- Suspension: Intermediate hanger bearings (maintenance-free polymer).

- Trough/Barrel:

- Performance Metrics

- Pressure Rating: Up to 1.6 MPa (pressure-rated barrel variants).

- Inclination Limit: 0–30° (horizontal); 60–90° (vertical).

- Noise Level: ≤72 dB(A) at 1 m.

- MTBF: ≥25,000 hours (corrosion-resistant components).

Design Innovations

- Quick-Change Screws: Tool-free disassembly via split trough design.

- Smart Lubrication: Centralized grease distribution with IoT monitoring.

- Anti-Bridging: Integrated fluidizing decks or vibration-assisted flow.

- Explosion Protection: Passive suppression vents + HRD isolation valves.

- Multi-component additive dosing in polymer compounding.

- Hazardous material transfer under inert gas (N₂/Ar) blanket.

- Precision feeding for FCC catalyst regeneration systems.

Compliance & Standards

- Mechanical Safety: GB/T 15706-2012 (Risk assessment for ATEX zones).

- Hygienic Design: GB 4806.1-2016 (Material migration compliance).

- Welding Standards: GB/T 12467-2017 (Pressure vessel fabrication).

- CIP/SIP-ready sanitary design (3D finish ≤0.8 µm Ra).

- Torsion monitoring system with overload auto-shutdown.

- Explosion-proof weighing modules (OIML R60 Class 0.2).

- Cryogenic cooling jackets (-196°C LN2 compatibility).

Operational Advantages

- 30% Space Savings: Vertical multi-screw units replace conventional conveyors.

- Zero Contamination: FDA-grade seals for pharma-grade applications.

- Energy Recovery: Regenerative drives capture deceleration energy.