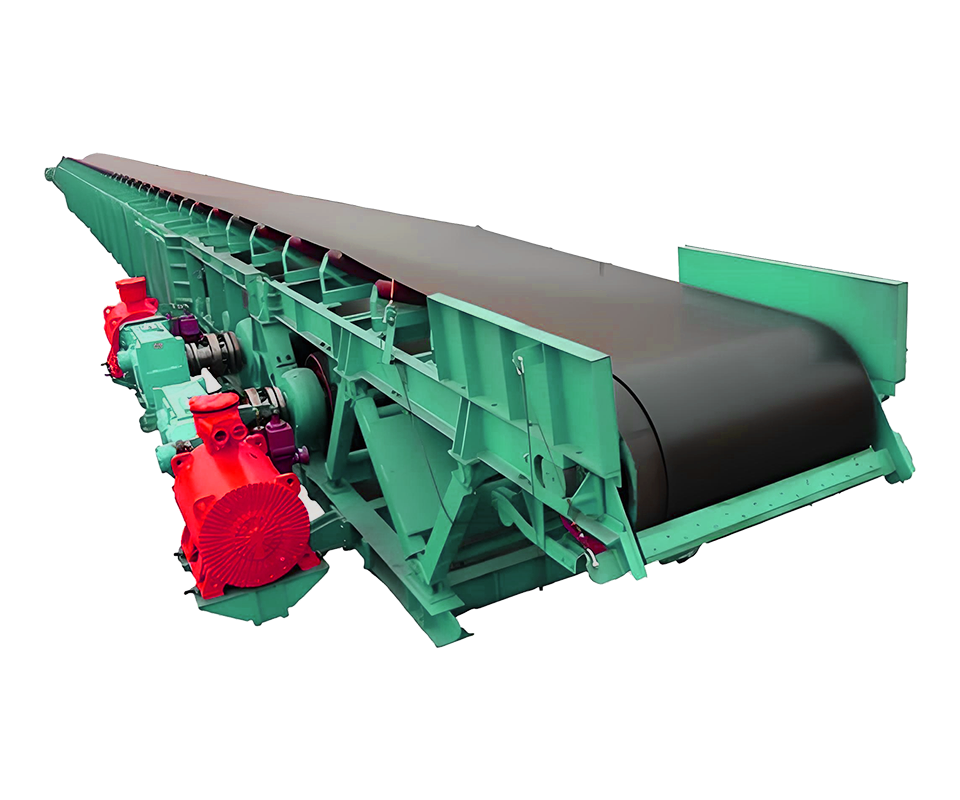

Standard Belt Conveyors

Standard belt conveyor for bulk material transportation with simple structure and wide applicability.

The General Purpose Belt Conveyor is a versatile bulk material handling system designed for efficient transportation of loose or packaged goods across industries such as mining, agriculture, logistics, and manufacturing. Engineered for durability and operational safety, this conveyor system excels in medium-to-long-distance material transfer with minimal energy consumption. Its modular design allows customization to meet diverse industrial requirements while adhering to national safety and performance standards.

Key Applications

- Mining & Quarrying:Transporting coal, ores, aggregates.

- Ports & Logistics:Loading/unloading containers, bulk cargo.

- Manufacturing:Assembly line material supply, finished product sorting.

- Agriculture:Grain, fertilizer, and crop handling.

- Structural Specifications

| Parameter | Range |

| Belt Width (BW) | 500–2,000 mm (customizable) |

| Belt Speed | 0.8–4.0 m/s (adjustable) |

| Conveying Capacity | 50–2,500 t/h (material-dependent) |

| Maximum Inclination Angle | ≤18° (standard) / ≤28° (cleated belt) |

| Roller Diameter | Drive Roller: Φ300–800 mm |

| Return Roller: Φ89–219 mm | |

| Troughing Idler Angle | 20°–45° (3-roller design) |

- Drive System

- Motor Power:2–200 kW (frequency-controlled options available).

- Reduction Gearbox:Hardened alloy steel, service factor ≥1.4.

- Belt Tensioning:Vertical gravity take-up or screw tensioner (complies with GB14784-2013 Section 4.1.4 for safety guarding).

- Belt Specifications

- Material:Multi-ply fabric (EP/NN), steel cord, or heat-resistant rubber.

- Top Cover Thickness:3–10 mm (abrasion-resistant compound).

- Tensile Strength:300–3,500 N/mm.

- Safety Features

- Hazard Zone Guarding:

- Roller nip points guarded per GB14784-2013 Section 4.1.3.6 (protective plates for pressure wheels and idlers).

- Vertical tensioning zones enclosed with 2.5 m-high protective panels and warning signs.

- Emergency Stop:Pull-cord switches at 20–30 m intervals.

- Anti-Skid Measures:Ceramic lagging on drive rollers.

- Environmental Tolerance

- Operating Temperature: -20°C to +60°C.

- Humidity: ≤95% RH (non-condensing).

- Dust Protection: IP55-rated electrical components.

- High Efficiency:Optimized belt geometry reduces spillage; ≥90% energy transfer efficiency.

- Low Maintenance:Sealed bearings, replaceable impact bars, and modular components.

- Safety Compliance:Full adherence to GB14784-2013 for mechanical hazards prevention.

- Customization:Configurable length, incline, discharge points, and belt types.

- Frame: Laser-cut carbon steel with hot-dip galvanizing (ISO 1461).

- Welding: AWS D1.1 standards; non-destructive testing (NDT) for critical joints.

- Certifications: CE, ISO 9001, and GB14784-2013 conformity.

- Footprint:Pre-engineered bolt-on supports for fast deployment.

- Lubrication:Centralized auto-greasing system (optional).

- Warranty:18 months for core components.